For JSC Ural Plant Zenit in development of production and execution of services of the civil direction extension of the list of the orders executed for the companies working in oil and gas sector of economy, in particular, for Tengizshevroil LLP, Karachaganak Petrolium Opereyting B. century, Nort Kaspian Opereyting Company at Kashagan, etc. is vital.

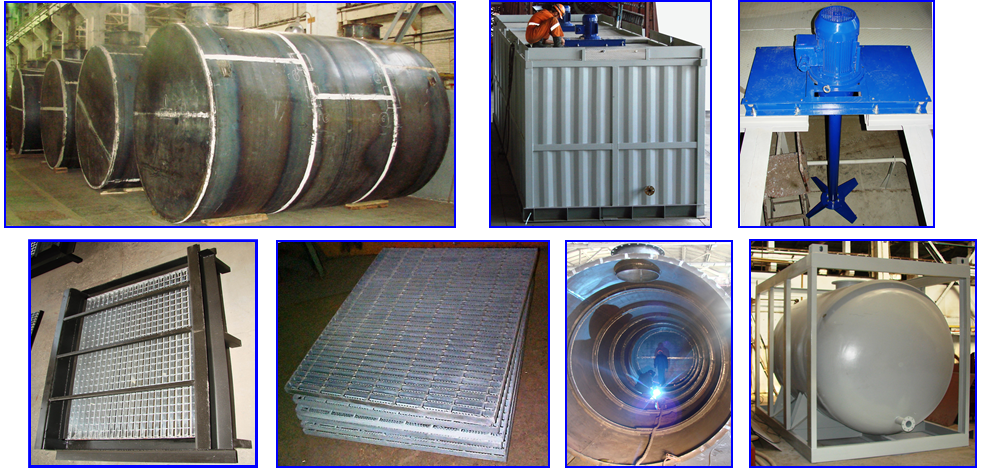

For these companies the plant is ready to start manufacture of the equipment according to the ASME, API specifications, repair and to participate in its service, having rather wide experience and in this sphere. Among the made production – a metal construction (steel structures of varying complexity, capacities up to 100 m3, platforms, platforms, frames of buildings, metal floorings), barriers, gate, pipe support, pipe products (flanges, a fitting, an attachment of high strength, etc.), the non-standard equipment. Services – maintenance of the equipment, testing of welded connections and materials.

Main types of operations and the rendered services:

Now the plant performs works for the firms accredited on oil-gas condensate fields of the Republic of Kazakhstan on the following directions:

1. Design and manufacture of metal building constructions of buildings and constructions, galvanized lattice floorings and steps of ladders of nonskid type, galvanized (including necessary fasteners) staircases, step-ladders in sets, platforms of service, pipe support.

2. Manufacture a flange-fitting of products on ASME, API and GOST, including mating rings of oval section from stainless steel on ASME, API and GOST:

- A fitting threaded (stubs, adapters, the union) from ferrous and non-ferrous metals.

- An attachment in metric and inch execution (including a flange-mounting attachment and anchor bolts) without restriction of types and the sizes on the ANSI, API and GOST specifications.

3. Design, manufacture, repair, testing, modification and mounting: the capacities working under pressure; tanks with mixers for storage of boring solutions; adjusting and shutoff valves; technological pipelines and filters; heat exchangers; oil coolers, and also blinds on air coolers of heat exchangers

4. Repair of the equipment:

- Technological pumps.

- Electrical motors.

- Spherical easels.

- Valves.

- Flow regulators.

5. Manufacture of orifice flow meters with a diameter up to 1600 mm.

6. Manufacture of cogwheels:

- straight-toothed and helical of transmission from m=0,3 to m=8,0 with outside diameter to 500 mm and 100 mm cut wreath wide.

- Conical toothed linkages from m=1,5 to m=4,0.

- A cutting tool for cutting of worm couples from m=0,3 to m=8,0 with an outside diameter up to 500 mm and slit couples with an evolving linkage and an angle of a profile of 30 degrees.

7. Manufacture of a cutting tool for metal working, mounting and special in metric and inch execution, including keys of percussions.

8. Manufacture of sealing elements metal, graphite, fluorine plastic and caroling, rubber (baffles, diaphragms, spacers, etc. with a diameter up to 770 mm) and plastic (up to 300 cm ³) on ASME, ANSI, API and GOST.

9. Design and manufacture of the load-lifting cable equipment, shipping frames and containers, for use, both on the land, and in the sea, and also lifting elements.

10. Rendering of services of a staff and equipment for carrying out service.

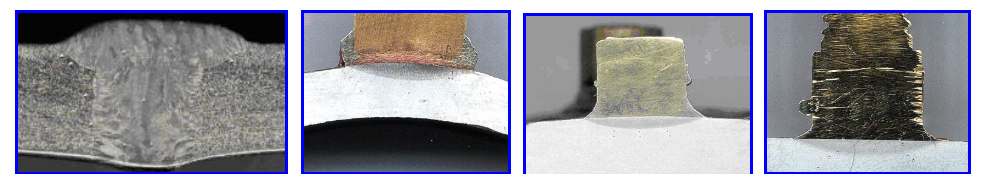

11. Execution of the following types of operations by the Central Factory Laboratory (CFL):

- Test of welded compounds of metals on stretching, a bend, a bend of the sides, a notch fracture, impact strength on the Sharpie with V and U – figurative notch, according to requirements of ASME, API, GOST and Construction Norms and Regulations.

- Testing of tee connections for corrupting.

- Determination of hardness of HB, HRC, HV.

- Macro photo of examinees of samples of materials and welded connections.

- Color testing (Penetrate-test).

- Ultrasonic and X-ray monitoring.

- Chemical analysis of metals.